A Quick Introduction

What Is Trashpresso?

The TRASHPRESSO is a solid waste recycling line. The assembled unit is made up of a 40-foot container housing the processing line and a 20-foot solar cell unit, separately. Both units are land, sea and air transportation ready.

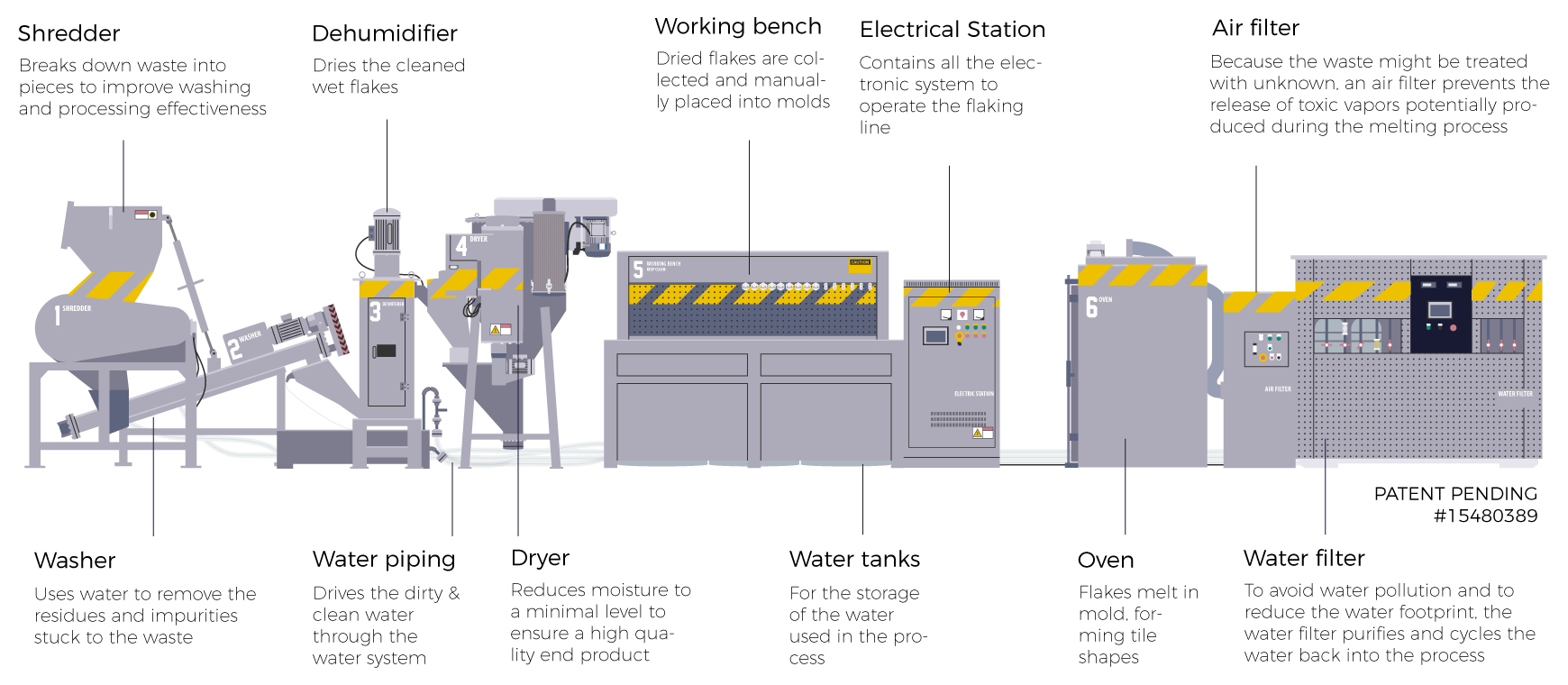

The TRASHPRESSO compacts the recycling process into three simple steps: size reduction, purification, reshaping. Additionally, we safeguard for environmental discharge from the process line operations with air and water filtration.

This recycling process line at present transforms plastic trash into a robust low-cost housing product. There are currently two such Trashpresso in activity around the world

From Trash To Tiles

A Recycling Idea

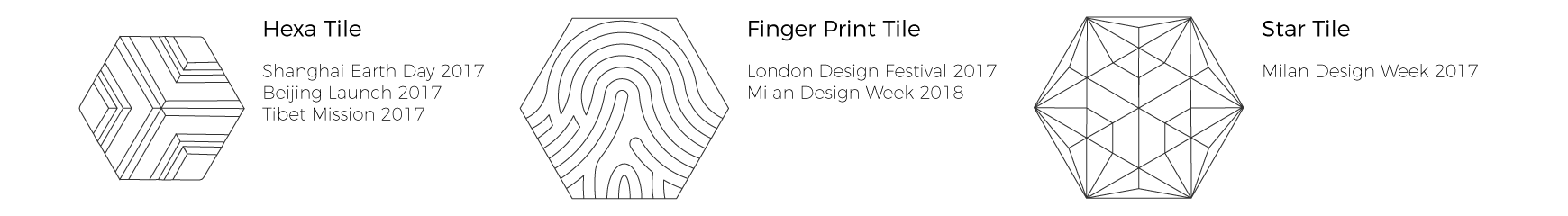

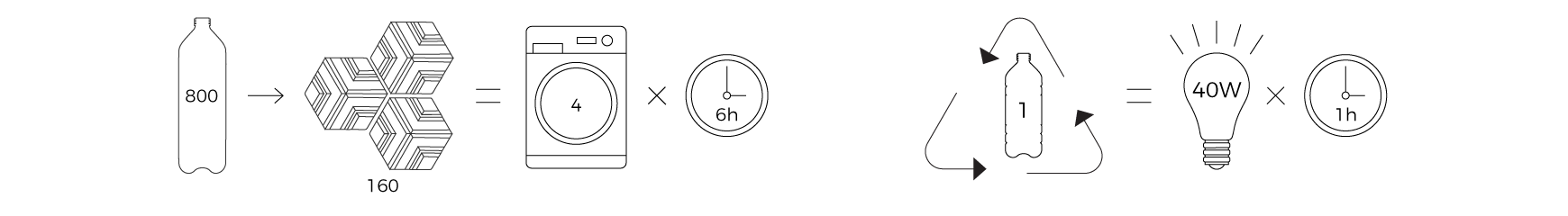

The TRASHPRESSO can upcycle up to 50Kg of waste per hour! Waste is converted into architectural tiles that have both a utilitarian and raw material value.

These tiles are versatile and resistant, allowing for a wide variety of applications. They can be used decoratively as interior or exterior decoration finishes or serve as flooring and supplement insulation.

Waste compressed into tile format is less costly to transport, facilitating industrial scale up. For example while at a recycling plant, the tiles can be up-cycled through cycles such as yarning, injection, or extrusion.

The TRASHPRESSO can upcycle polymers into thermoplastic that have a melting point lower than its burning point.

Tiles Already Developed

Trashpresso 1

The Asiatic Recycler x Jackie Chan

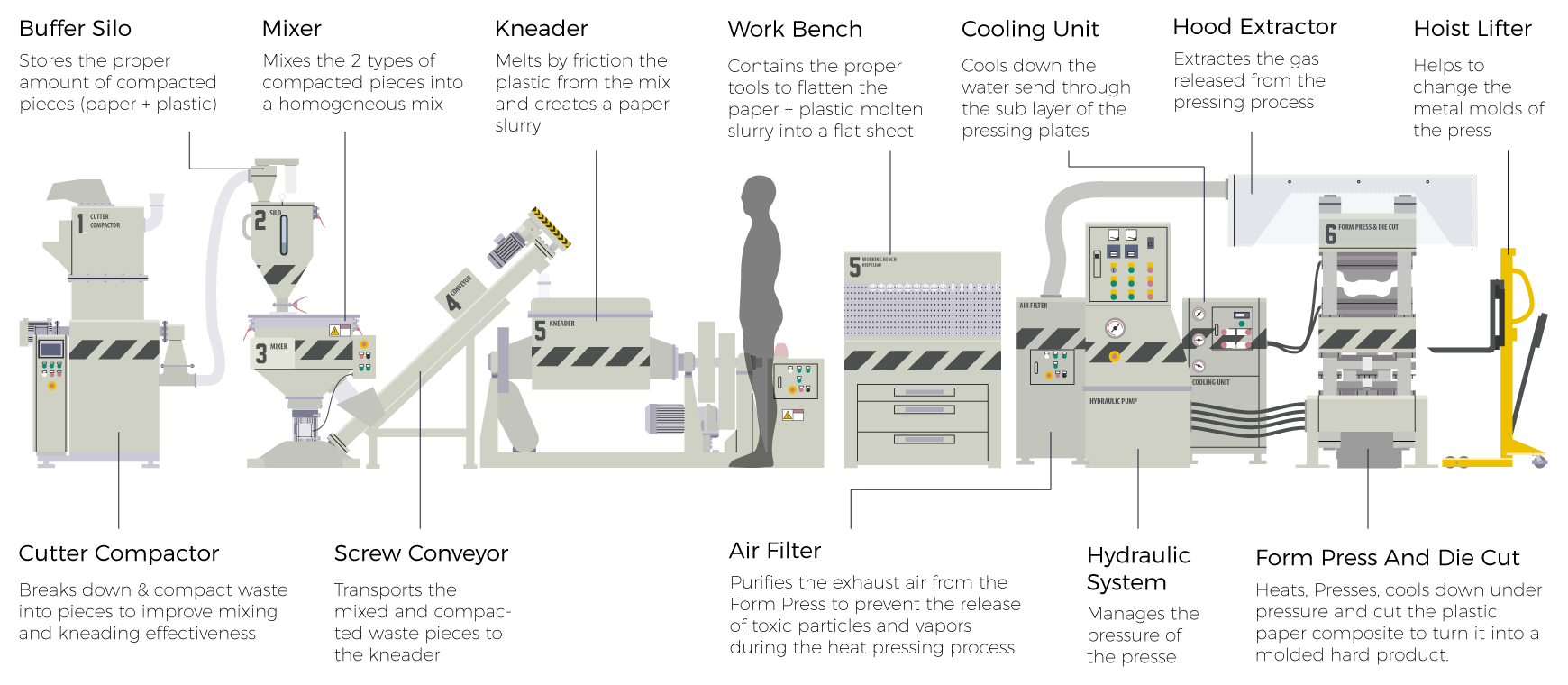

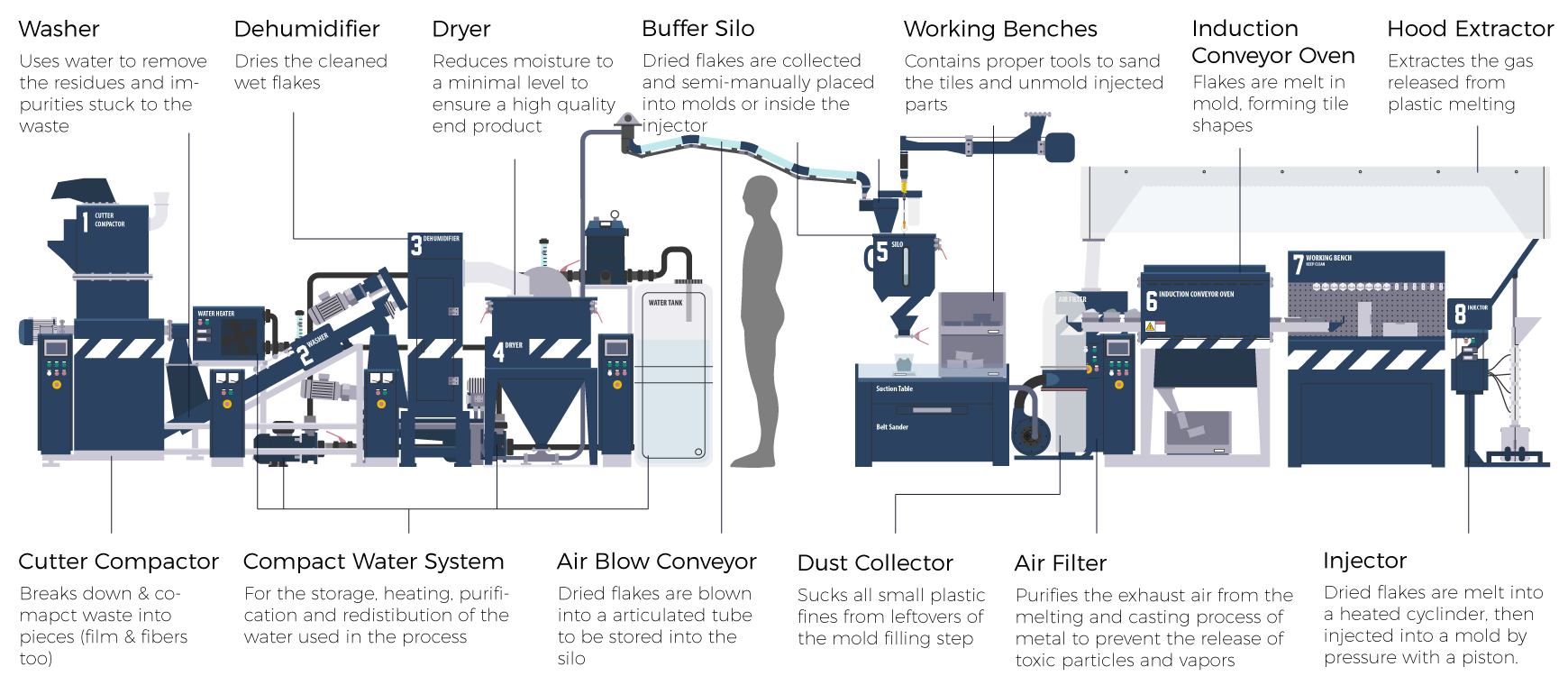

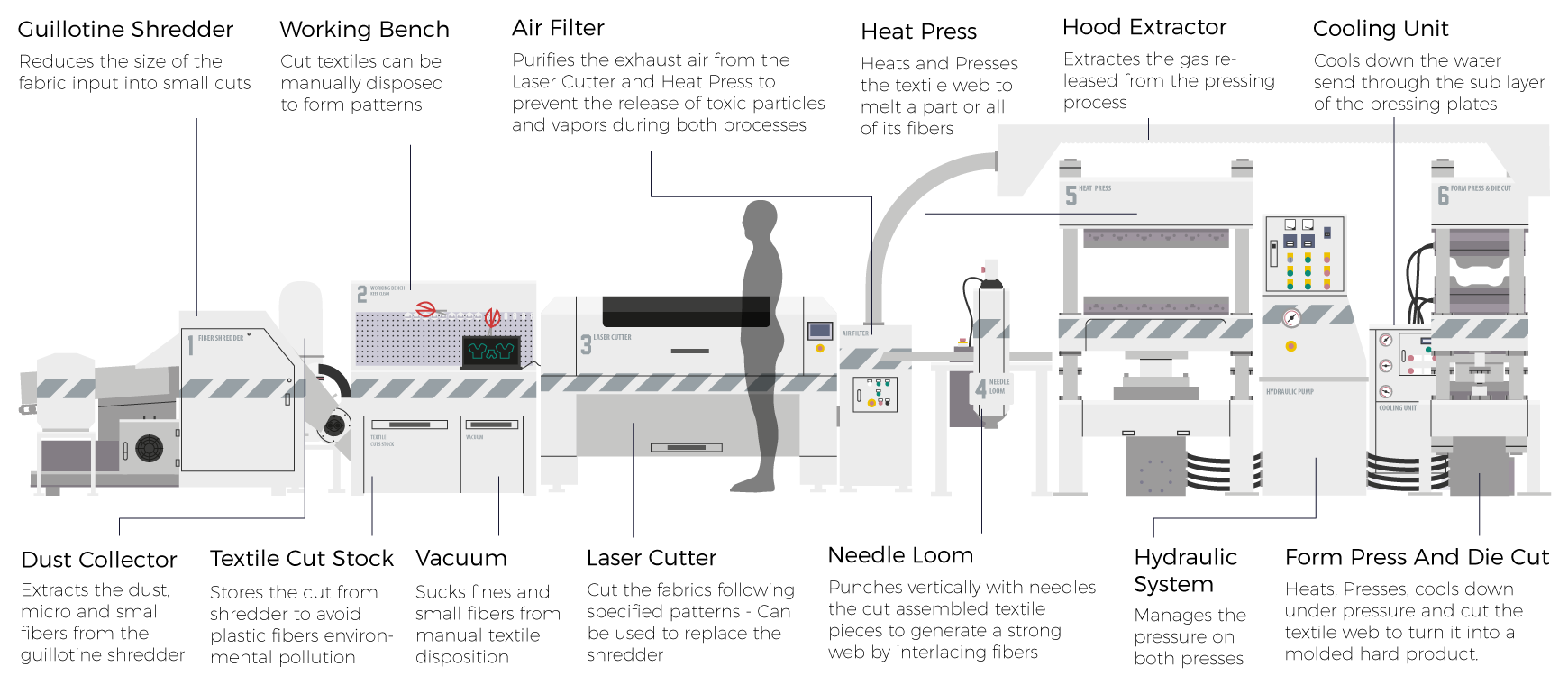

Illustration of the recycling line of the TRASHPRESSO 1:

Trashpresso 2

The European Recycler

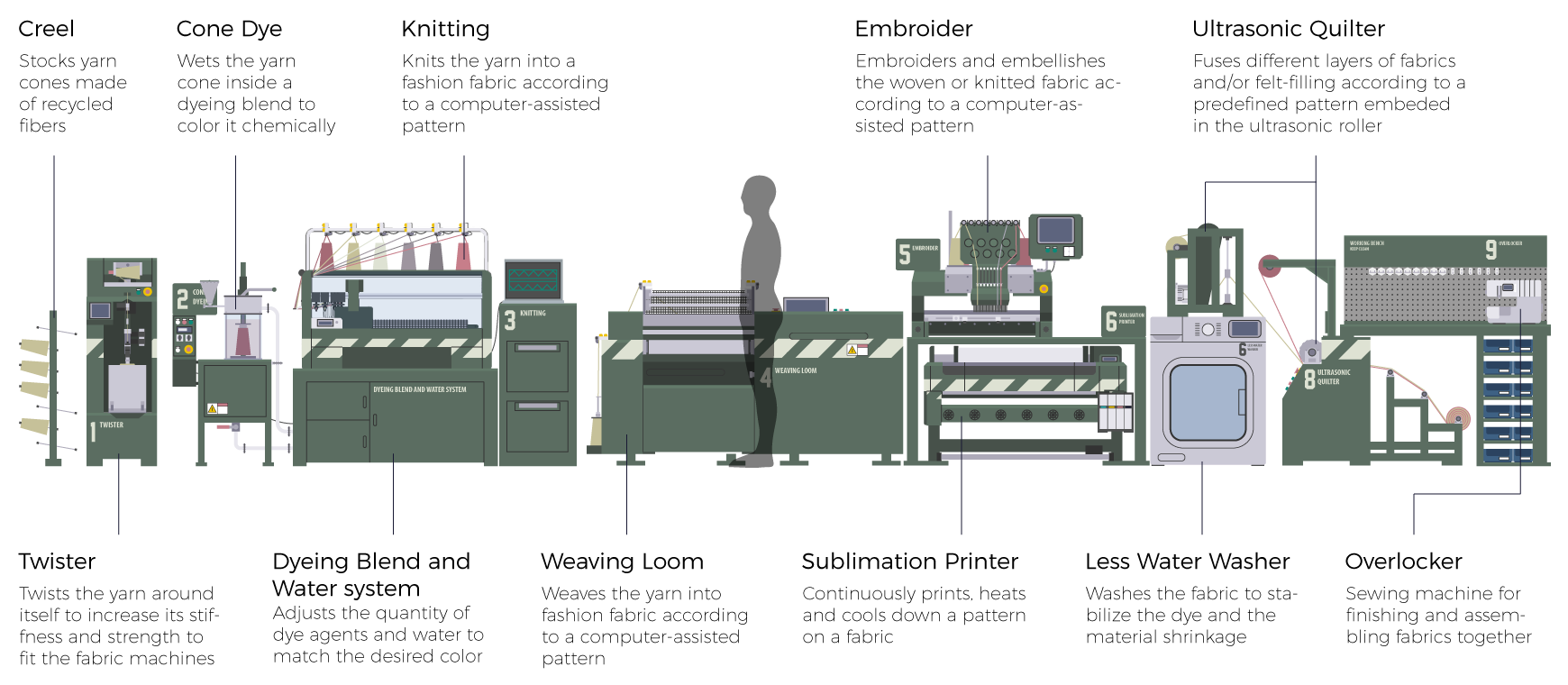

Illustration of the recycling line of the TRASHPRESSO 2, the line is subdivided into 2 independent 20-foot decks for more portability:

Energy

A Renewable Power

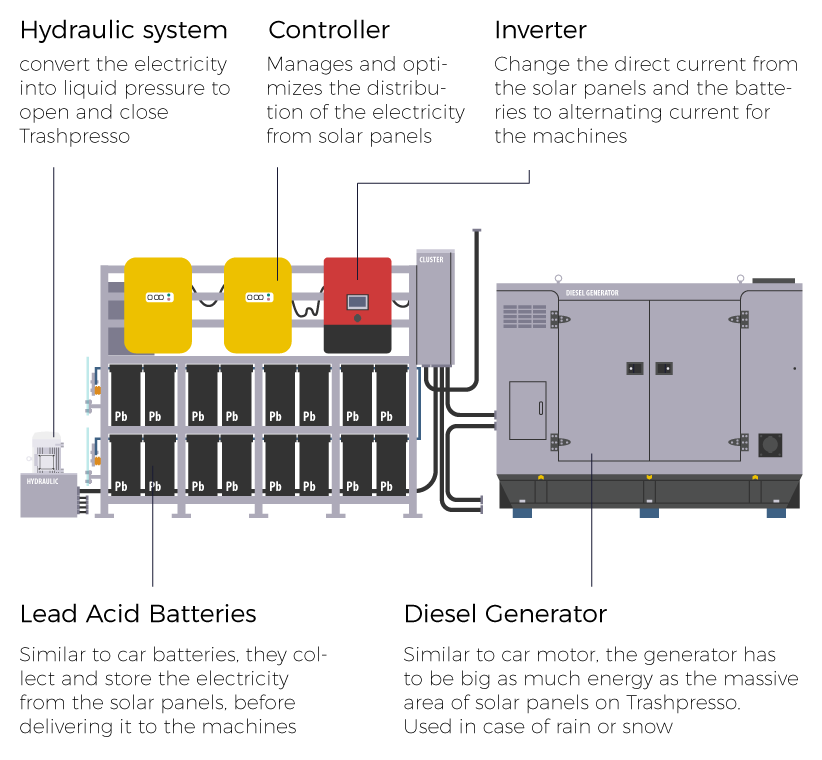

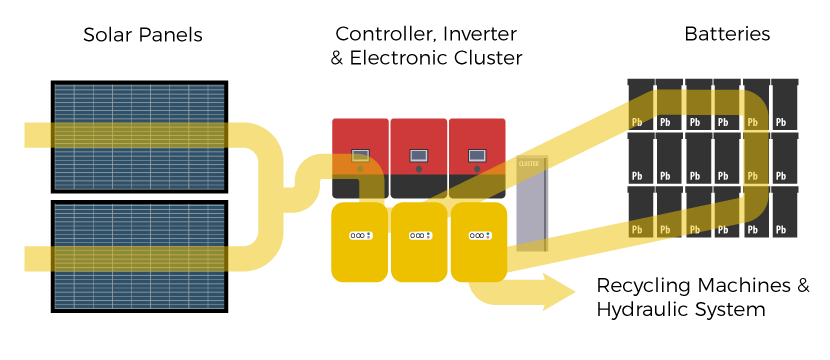

All TRASHPRESSOs share the same solar power system as it’s energy source. Both containers (the recycling process line and the energy storage unit) solar panels are activated by the radiation of the sun. They turn that energy into electricity and, send it to storage and monitoring.

Electric actuators operate the solar panels inclination, maximizing their efficiency. They are situated on the roof of the TRASHPRESSO, as wings. A hydraulic pump rises up the pressure into hydraulic actuators to lift the roof for a perfect deployment of the solar panels, as wings. These systems are, as well, fed by the electricity stored into the batteries.

To mitigate the risk of relying solely on solar energy the TRASHPRESSO is also equipped with a backup diesel generator.

The Diesel generator has been partially used for Trashpresso 1’s Tibetan Mission due to the continuous snowing condition.

The TRASHPRESSO requires 40.5 kW during a cycle of 6 hours to operate all of its machines and filters. The energy provided by a solar powered battery that can store up to 80 KW per charge.

In case of bad weather, 2 recycling cycles (12 h) can be operated with the stored energy before the system runs out of energy. The time to store that energy depends on the location and on the weather.

52 Working Days

How Much is 40.5 kW Of Power ?

Water

Tend To Zero Footprint

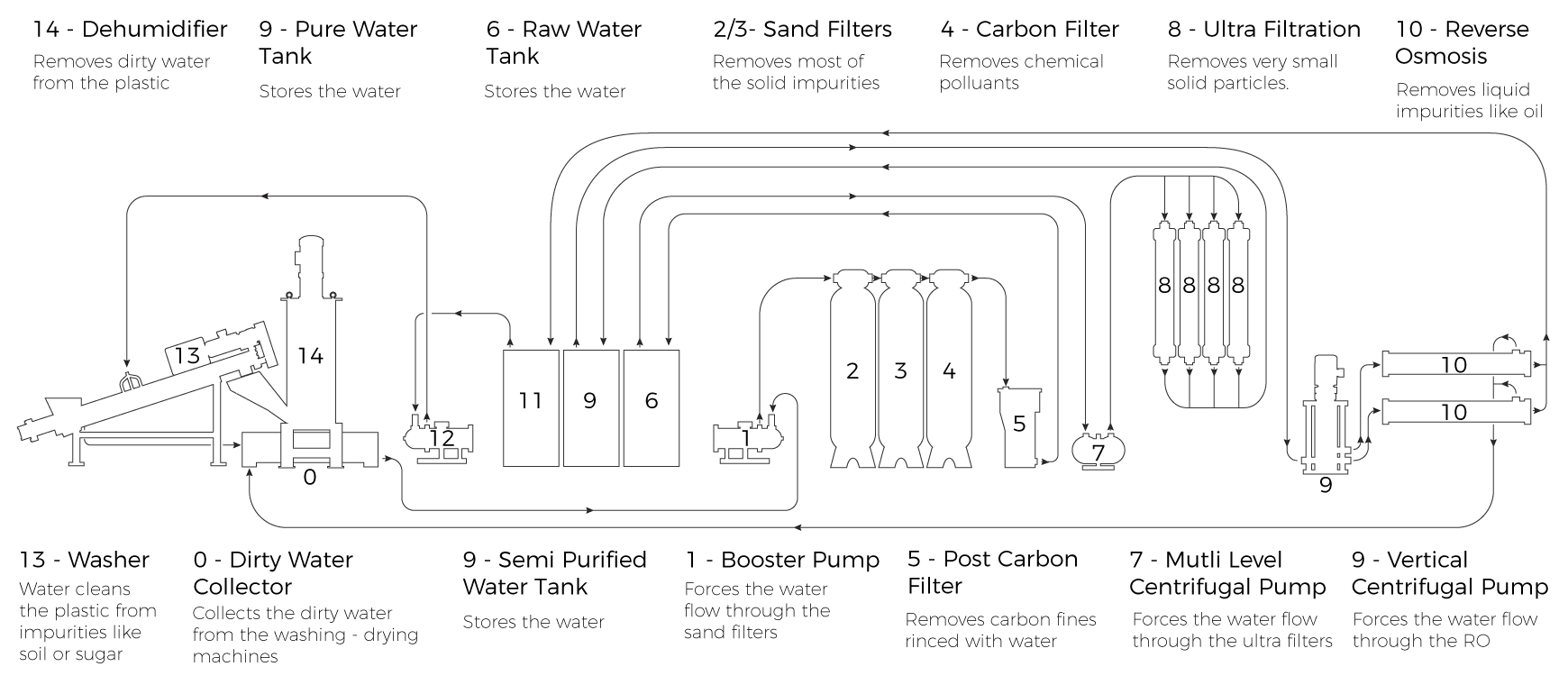

The TRASHPRESSO recycling processes use 100 L of water. No water is lost in the process as it is looped back through three steps of filtration: quartz sand filter, ultra-filtration, and reverse osmosis.

Trash Source

An Appendix Of Recycling Data

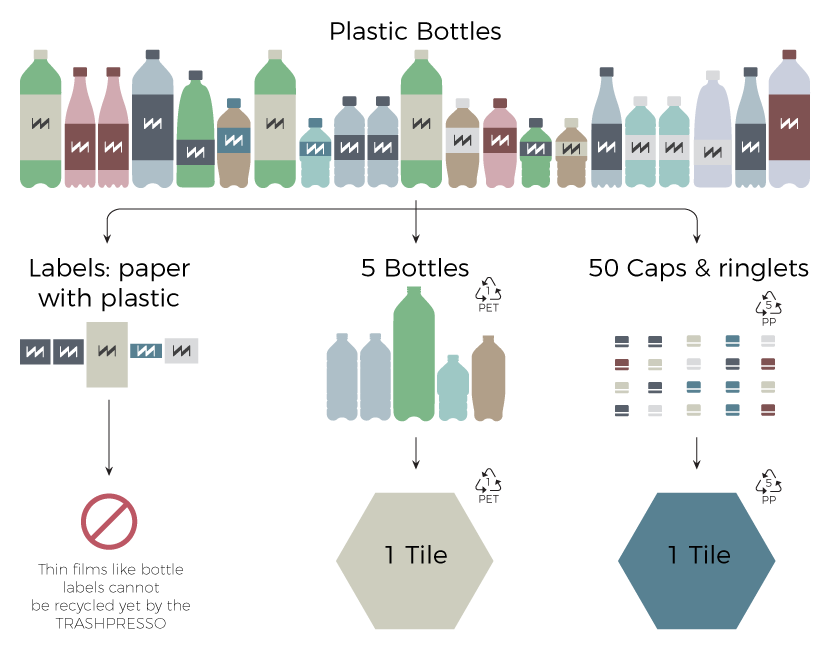

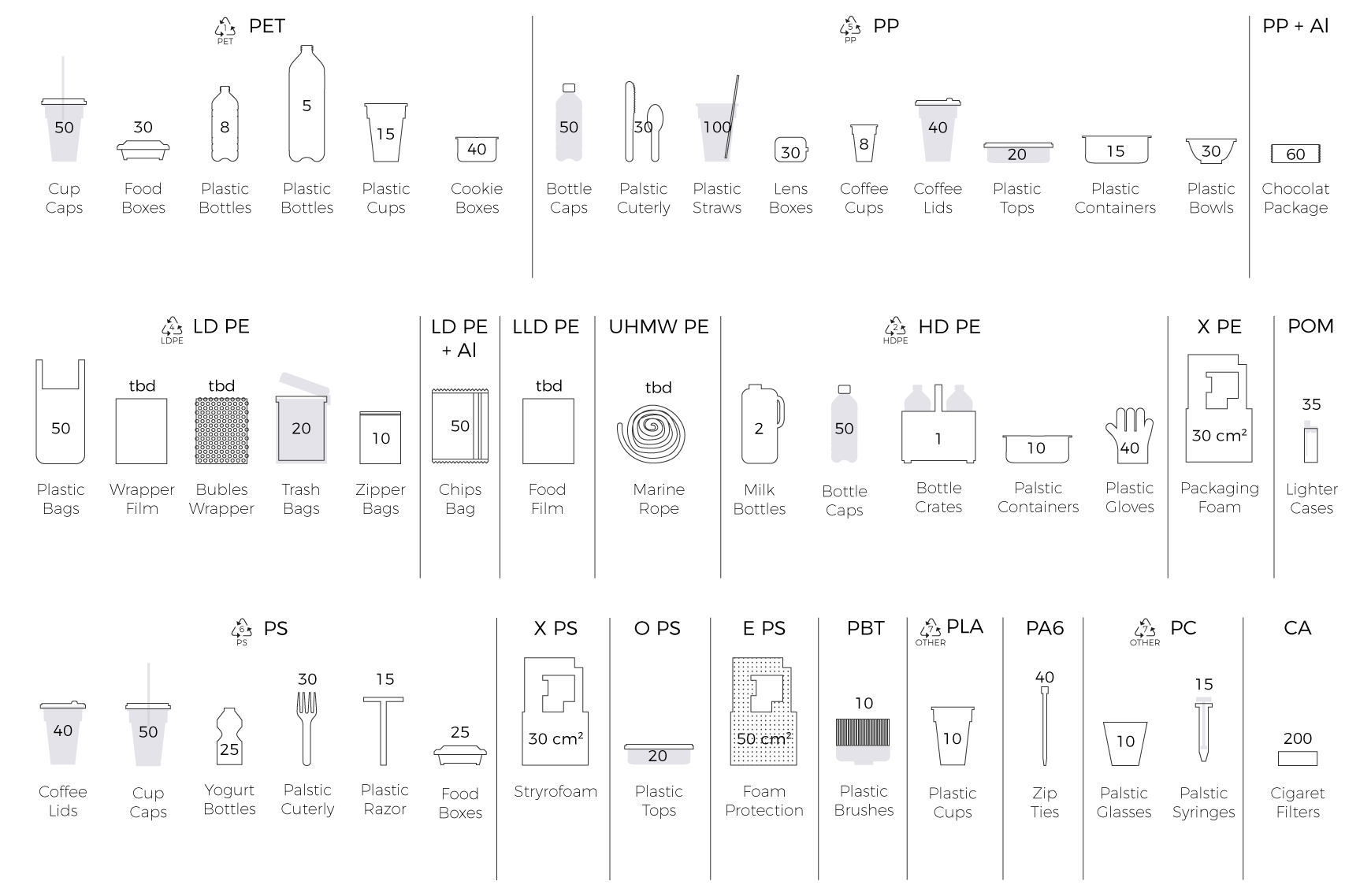

Plastic trash comes from disposable items with a single use. A same item as the bottle cap can be made from different plastics. For recycling, plastic marking is very important. Not all the disposable items are very well recycled. The TRASHPRESSO can recycle all of them once they are correctly sorted. The numbers represent the amount of one trash type to be trasnformed into one Hexa Tile.

~ 2550 Tiles made

PS

0%

PET

0%

PP

0%

Other

0%

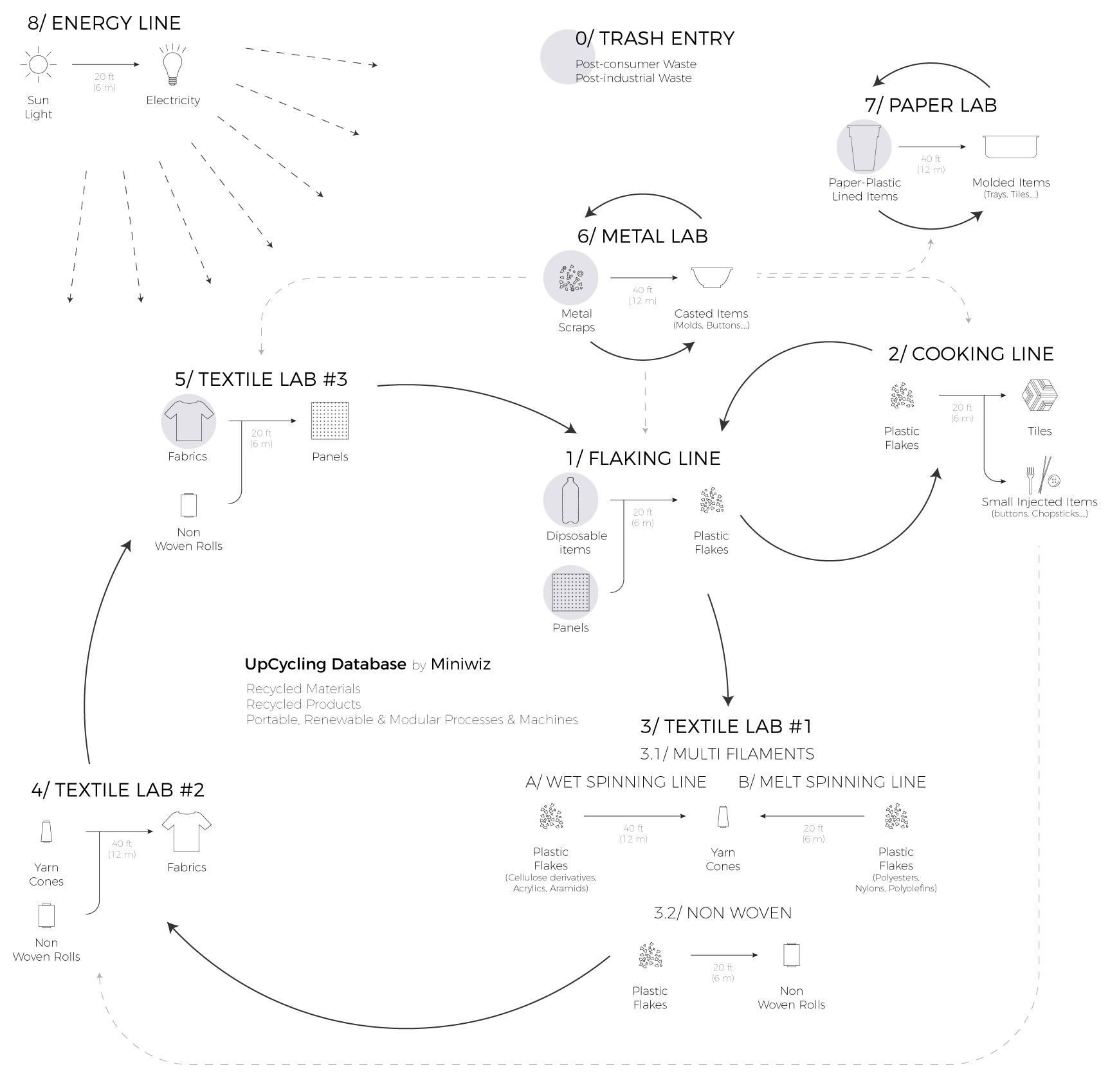

The Trashpresso Concept

True Circular Economy

The developed TRASHPRESSO (Flaking, cooking and energy lines) is part of a bigger plan to enable the circular economy. It involves open access to recycled material and product data and shared knowledge about polymers.

Additionally, Miniwiz’ R&D team is developing new portable recycling lines that work independently or together in a closed loop.

A recycling line can even be extended by a part of another one to produce a different outcome. They will recycle paper lined with plastic, metal and textile trash to turn them into sexy products, ready to be consumed and recycled again.

-

Want to know more?

The American Recycler — Coming Soon

The TRASHPRESSO 3 is under development at Miniwiz R&D Lab in Taiwan and Germany. Based on all the experience returns from previous TRASHPRESSO, the recycling line is being improved. The focus is:

– Reduce the risk of plastic dust pollution through the process.

– Improve the speed of material transformation and its continuity.

– Improve the purity of the material.

-Develop more shaping options than tiles.

– Compact the size and weight of the recycling line.

No longer containers are needed and two simple truck trailers will complete the transport of the units. The solar panels will be flexible. Machines from Precious Plastic Project are included in this recycling process line, such as the like’s of the injection molding manual machine

The Home Recycler — Coming Soon

A compact and movable recycling line, based on Trashpresso 1 & 2, with the size of any big domestic appliance. Ideally powered by renewable energy, but also by city grid. Miniwiz R&D Lab in Taiwan is working on a new solution to trash pollution.

Trashpresso Fabric Edition

The Circular Textile Lab #3 — Coming Soon

The TRAHSPRESSO Textile Edition focus on fabric waste treatment. The leftover fabrics will be transformed into hard molded panels.

Trashpresso Yarn Edition

The Circular Textile Lab #2 — Coming Soon

The TRAHSPRESSO Yarn Edition focus on recycled yarn embellishment. The yarns will be transformed into woven or knitted colored fabrics.

Trashpresso Filament Edition

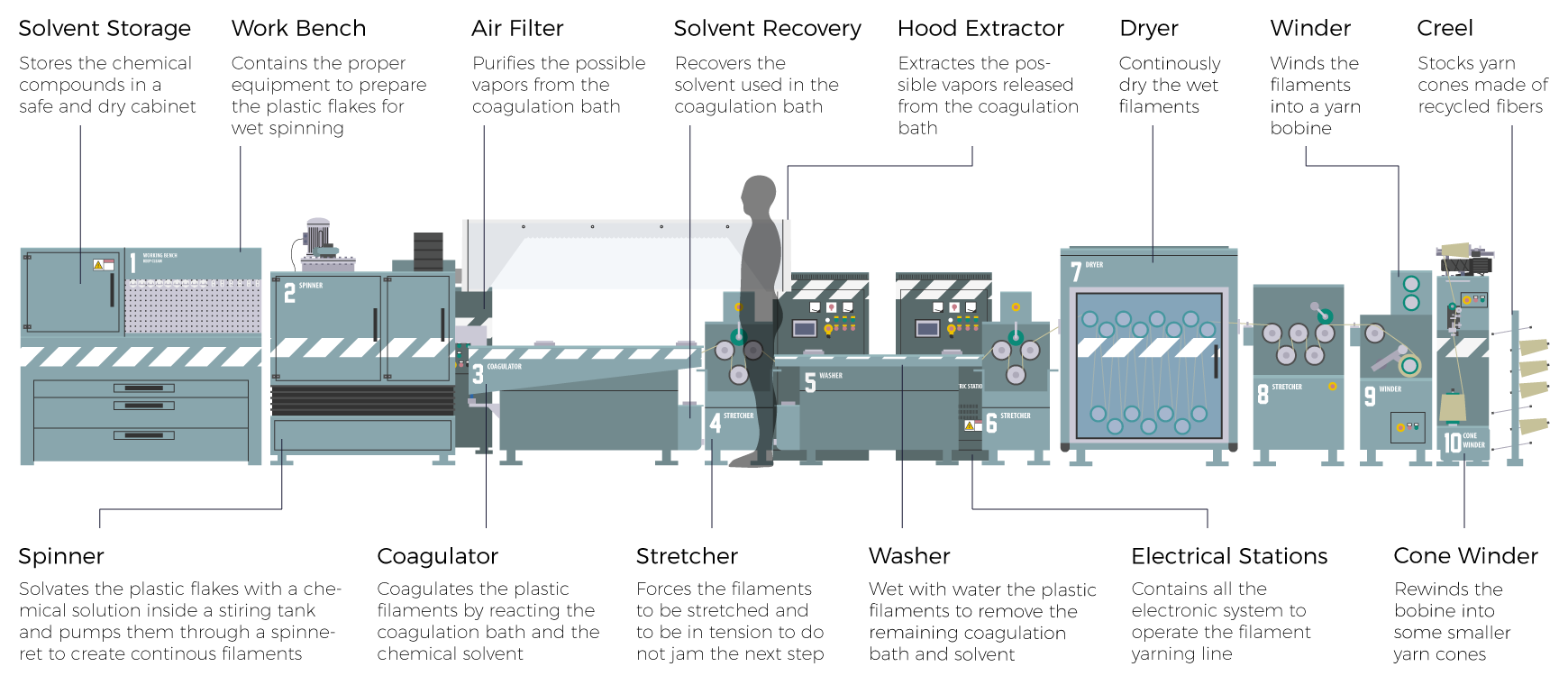

The Circular Textile Lab #1 — Coming Soon

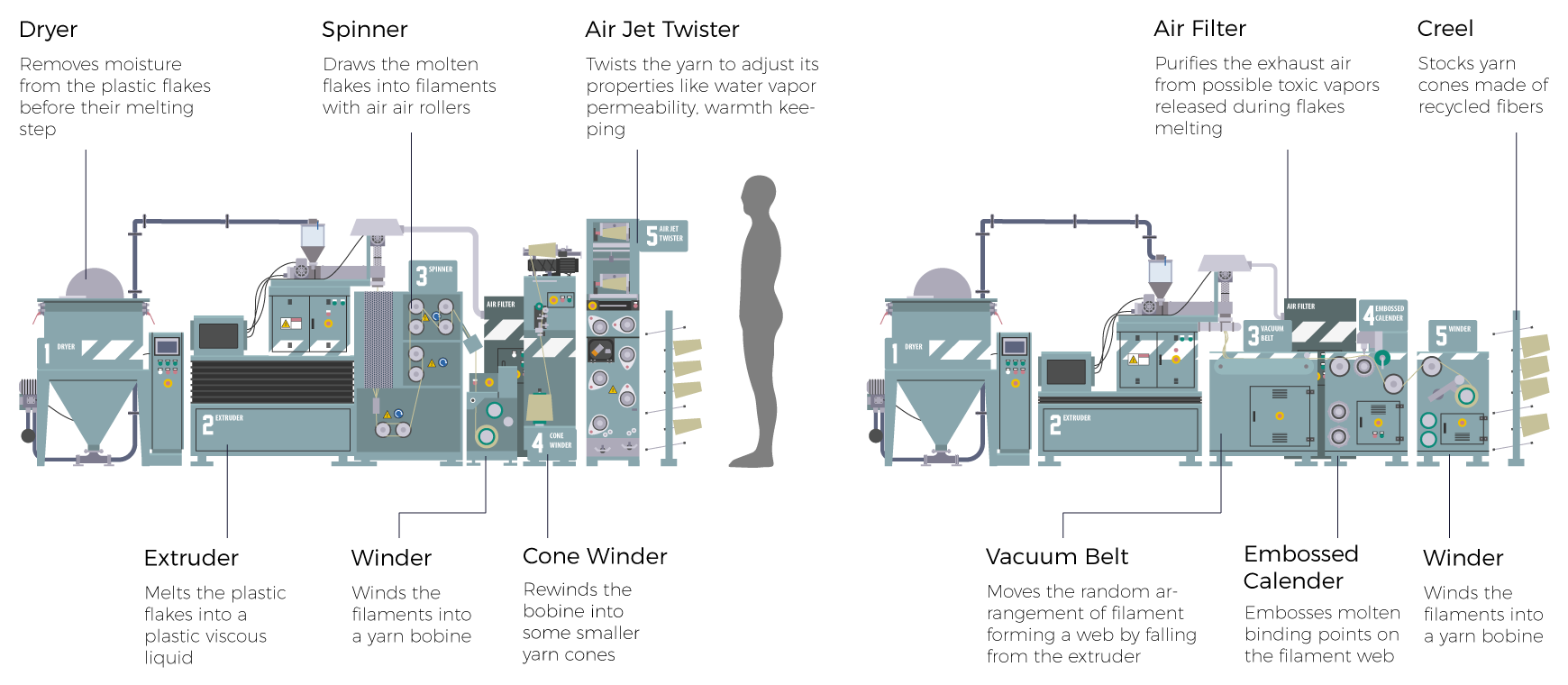

The TRAHSPRESSO Filament Edition focus on turning plastic waste into fibers that can be later turned into fabrics by the TRASHPRESSO Yarn Edition, used and recycled again through the TRASHPRESSO Textile Edition. The Filament Edition exists in 3 different versions, based on the type of polymers to recycle and the outcome product.

Option 1, the plastic waste is melt (A) or dissolved (B), spun through tiny holes, oriented and twisted to form multi-filaments yarn.

Option 2, the plastic waste is melt and spun through tiny holes, randomly blended and thermo-reinforced to form non-woven.

Melt Spinning (Option 1.A + Option 2)

Melt spinning process is suitable for Polyester family (like PET), part of Nylon family (like PA6) and Polyolefin family (like PP).

Wet Spinning (Option 1.B)

Wet spinning process is suitable for Cellulose derivative family (like CA), part of Nylon family: Aramide (like PPD-T) and Acrylic family (like PAN).

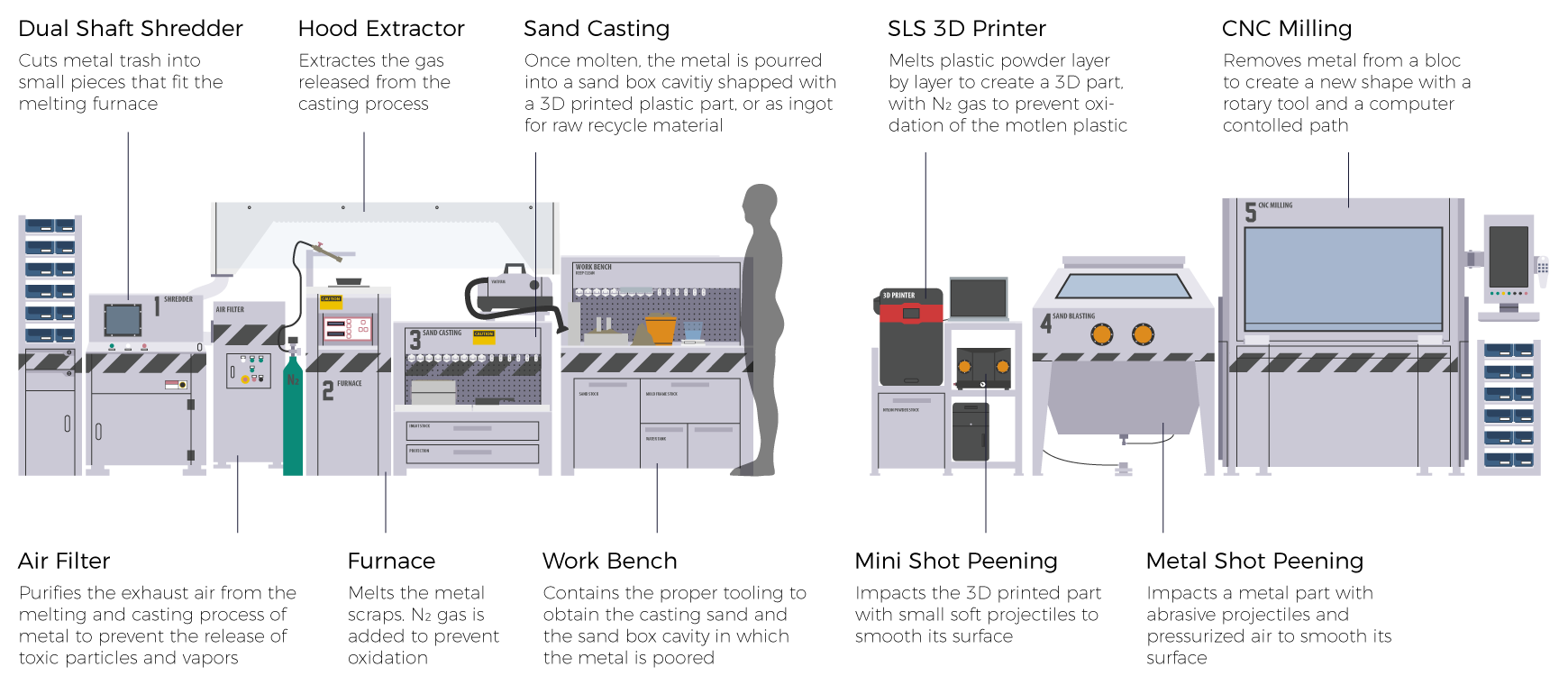

Traspresso Metal Edition — Coming Soon

The TRAHSPRESSO Metal Edition focus on metal scrap regeneration. The metal, like an aluminum can, is shredded, melt into a furnace, cast into a new product, and refined with different finishing process. Other types of metal like copper, tin, brass, bronze, gold, silver, can be turned into new items like buttons for recycled textile clothes from the Circular Textile Lab, or into a prototype mold for any other TRAHSPRESSO line using the heat press process.

Traspresso Paper Edition

Miniwiz’ Taiwan Trashlab Compacted — Coming Soon

The TRAHSPRESSO Paper Edition focus on turning paper + plastic composite waste, like a coffee cup, into a new hard molded product by increasing the content of plastic from plastic film waste and melting the plastic around the paper. The process works also for metalized plastic film, like chocolate bar packaging, or rubber composite from a different type of trash like shoe soles or wetsuit. The product obtained from the coffee cup can be, for example, a recycling bin to collect more coffee cups, which will be turned by the same process into a bigger product, like a coffee table top.